HOME > Products

Products

Products

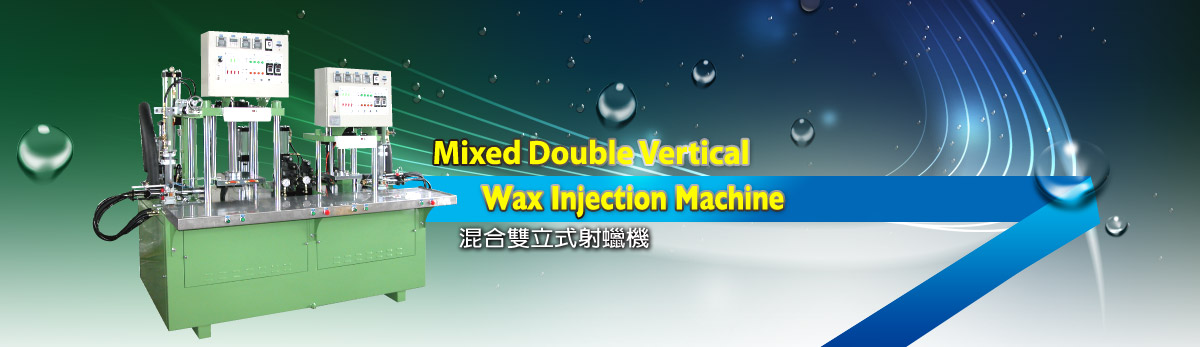

YP16A

Double Vertical Wax Injection Machine

Double Vertical Wax Injection Machine

Feature

1. Integrated double vertical wax injection machine

2. Double nozzles on both sides

3. Nozzle moves up/down hydraulically with left and

right adjustment

4. With upper/lower fixed molds and hand-push single/

double molds

5. With wax storage barrel for independent supply of wax

6. Stainless steel hand-push mold platform

7. 16t mold pressing force

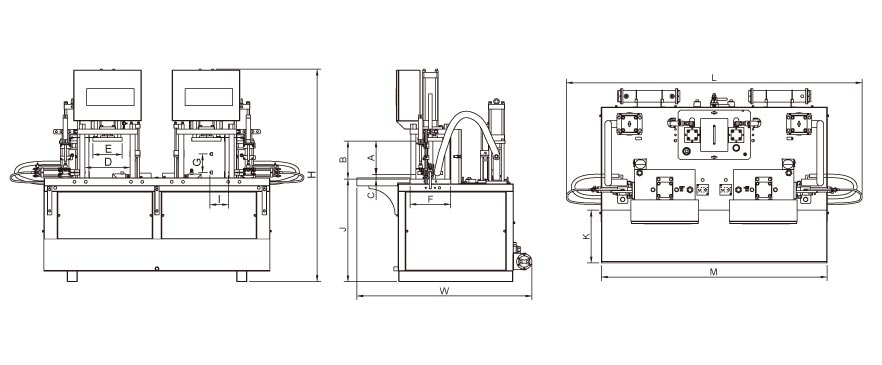

DESCRIPTION UNIT YP16A Mold clamping force ton 16 Mold clamping stroke(A) mm 400 Maximum opening(B) mm 500 Minimum opening(C) mm 100 Inner dimension(D) mm 500 Pressing plate width(E) mm 380 Pressing plate depth(F) mm 535 Nozzle height adjustment(G) mm 150 Nozzle advancing and retreating adjustment(I) mm 150 Working table height(J) mm 926 Working table depth(K) mm 470 Working table width(M) mm 2200 Machine’s external dimension(L x W x H) mm 2850×1666×2222 Mold clamping screws mm M12 Cooling caliber mm 12.7 Wax storage barrel volume L 90L Single injection capacity (wax cylinder) L 3 Injection pressure kg/cm² 10-100 Injection time sec 99.9 Nozzle aperture mm 6 Hydraulic oil pump L x kg/cm² 30×140 Hydraulic oil reserve L 150 Hydraulic oil cooling system YES/NO YES Voltage specification 60/50Hz 220V/380Vx3P Quantity of electricity consumed A 30×2 Heater capacity KW 3KWx2 Machine weight KG 2550 Nozzle upward/downward pressure YES/NO YES Nozzle left/right adjustment YES/NO Option - The machine is wax mold forming equipment for the dewaxing casting process.

- Golf ball head, valves, precision hardware parts, aerospace parts, etc.